- Messages

- 1,068

- Reactions

- 384

If I knew how to weld I'd probably do the same.

Was also trying to think about the Home Depot buckets they use in the parking lot with a little cement and a post in it. But I want to be able to remove the post when breaking down and taking home. Still think it's going to be too heavy though.

How about sinking a piece of PVC pipe in it slightly higher than the level of the cement? Then you could just drop a piece of 1x1 or whatever size you want to use for your post in it and staple the target to that

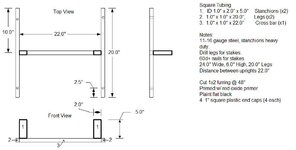

). I'd really like to keep them as light weight as possible, so no concrete and limited lumber involved. I think the style i posted with some improvemens from kevs stand is going to do be the most light weight, easy to disassemble, and packable (?) out of the styles i've seen so far. If you're worried about wind with the PVC stands, the youtube how-to i watched added hold-down stake holes to two of the legs of the stand, that could be pinned down in high wind.

). I'd really like to keep them as light weight as possible, so no concrete and limited lumber involved. I think the style i posted with some improvemens from kevs stand is going to do be the most light weight, easy to disassemble, and packable (?) out of the styles i've seen so far. If you're worried about wind with the PVC stands, the youtube how-to i watched added hold-down stake holes to two of the legs of the stand, that could be pinned down in high wind.