Silver Supporter

- Messages

- 591

- Reactions

- 271

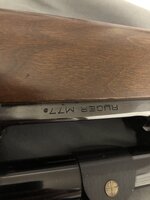

Hey all! I know this light seem dumb to ask, but I figure this would be the place to go if anywhere. Recently I purchased a Ruger m77 and fell in love with its beauty but it appears I overlooked some things before the transfer. When I went to put on a bipod I realized the slog swivel connector that goes into the stock was loose and the wood was stripped so attaching a bipod was pointless. I figured I should ask before I put epoxy in but is epoxying the pin into the hole my best option? What would you guys recommend or what brand wouod you guys use? Thank you all for any help I can get. I'll attach a photo be