- Messages

- 2,627

- Reactions

- 3,997

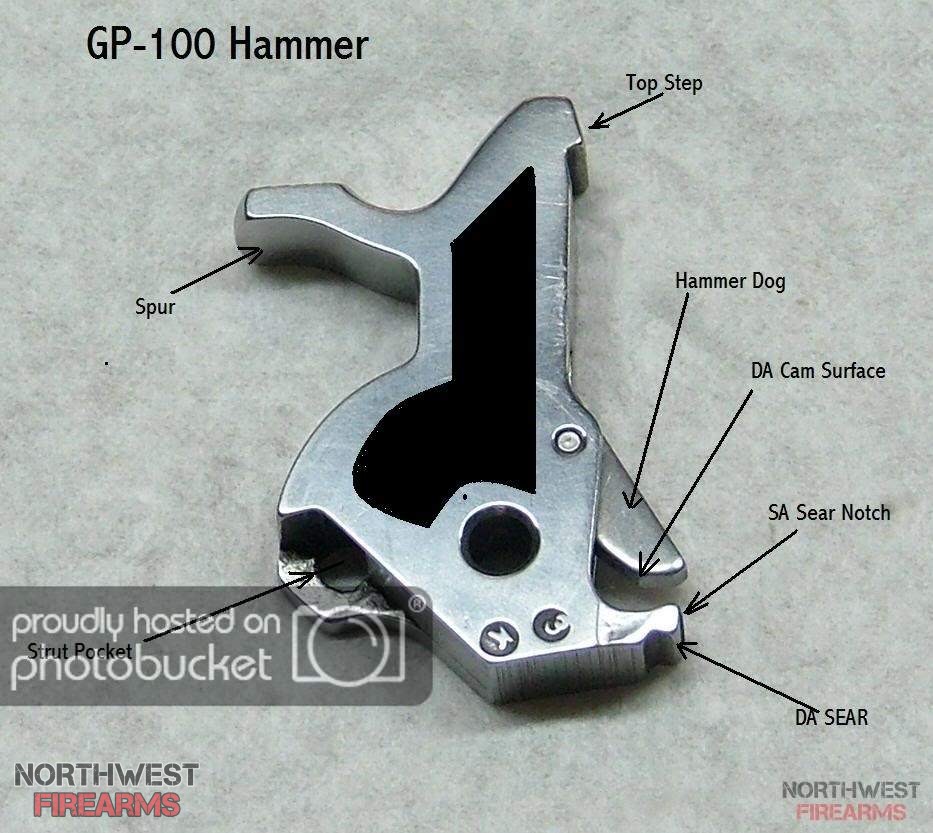

1) I'm about to do a shim, spring and polish on my GP100 and have a question about the sear engagement.

When shooting double action does the hammer trip from the hammer dog or does the dog release the hammer to another sear prior to release. I can't really see what's going on in the gun and can't find anything on this out in the cloud.

If is does release to a secondary sear where on the hammer is this surface?

2) Sometime after my GP100's manufacture date the factory started drilling an elongated hole in the backstrap of the grip stud to allow easier access and manipulation of the trigger guard latch. Does anybody have any recommendations of a Vancouver area machine shop that can drill this hole for me, and not charge a huge amount of money. I get set up time etc. but a couple of quotes I've received were over $200 and that is far more than I can stomach paying for a non-cosmetic hole.

Thanks folks!

When shooting double action does the hammer trip from the hammer dog or does the dog release the hammer to another sear prior to release. I can't really see what's going on in the gun and can't find anything on this out in the cloud.

If is does release to a secondary sear where on the hammer is this surface?

2) Sometime after my GP100's manufacture date the factory started drilling an elongated hole in the backstrap of the grip stud to allow easier access and manipulation of the trigger guard latch. Does anybody have any recommendations of a Vancouver area machine shop that can drill this hole for me, and not charge a huge amount of money. I get set up time etc. but a couple of quotes I've received were over $200 and that is far more than I can stomach paying for a non-cosmetic hole.

Thanks folks!