Navigation

Install the NWFA app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More Options

You are using an outdated browser

The browser you are using is likely incompatible with our website. We recommend upgrading your current browser or installing an alternative.

JavaScript is disabled

Our website requires JavaScript to function properly. For a better experience, please enable JavaScript in your browser settings before proceeding.

-

Join the #1 community for gun owners of the Northwest

We believe the 2nd Amendment is best defended through grass-roots organization, education, and advocacy centered around individual gun owners. It is our mission to encourage, organize, and support these efforts throughout Oregon, Washington, Idaho, Montana, and Wyoming.Free Membership Benefits

- Fewer banner ads

- Buy, sell, and trade in our classified section

- Discuss firearms and all aspects of firearm ownership

- Join others in organizing against anti-gun legislation

- Find nearby gun shops, ranges, training, and other resources

- Discover free outdoor shooting areas

- Stay up to date on firearm-related events

- Share photos and video with other members

- ...and much more!

Reloading bench pics

- Thread Starter Hotwheelz

- Start date

-

- Tags

- ammunition diy reloading

- Messages

- 3,115

- Reactions

- 6,599

Its always fun to see what the other guy uses. What works for some may not work for others. When I set up a reloading bench, I want my press to be fully supported and solid. Meaning a good brace under it and the press as close to a post as I can get (generally a 4x4 works well). Slightly elevate my beam scale, for better in line sight and accuracy. Other components to reloading like powder measure in a good accessible spot on the left hand side of the table, with room for my tray loaded with empty cartridges right in front of me. I like my reloading to be enjoyable and as much not like work as possible. I like a smooth transition from each stage to the next.

- Messages

- 261

- Reactions

- 199

I like my reloading to be enjoyable and as much not like work as possible. I like a smooth transition from each stage to the next.

Very well said. I love to reload. Weather it's cranking out rounds on my Dillon650 or my Lee single stage presses. I'm in the gun room having fun. I almost love it as much as shooting.

Happy shooting/reloading.

My loading setup a couple posts up is reflective on my return to long range BR. The scale/thrower/trickled on the left automatically throws the charge to the kernel. The scale sensitivity is .001 grains. The arbor seater measures seating pressure. I have one press dedicated to sizing the BR cases. The red trim/deburr/chamfer tool

is very fast an accurate. I leave it set up for the BR cases as well. I use AMP annealing machine on the right to anneal before each sizing operation. Not showing are my tools to measure rough characteristics and shape of the bullets.

That said, my wife says I need to come up with a nicer look if I want to keep reloading in my office. Probably a custom piece of furniture that will hide everything when not in use.

is very fast an accurate. I leave it set up for the BR cases as well. I use AMP annealing machine on the right to anneal before each sizing operation. Not showing are my tools to measure rough characteristics and shape of the bullets.

That said, my wife says I need to come up with a nicer look if I want to keep reloading in my office. Probably a custom piece of furniture that will hide everything when not in use.

Silver Supporter

- Messages

- 2,021

- Reactions

- 2,727

Bronze Supporter

- Messages

- 19,697

- Reactions

- 54,987

- Messages

- 381

- Reactions

- 529

I am definitely jealous!

- Messages

- 11,081

- Reactions

- 50,429

Thats looking amazing Jim. Nice job!!!

Bronze Supporter

- Messages

- 19,697

- Reactions

- 54,987

Thats looking amazing Jim. Nice job!!!

Thanks, it has been an experience that's for sure.

Anyone know someone that has crown molding installation experience in the Olympia area?

I have the pieces cut to length but every time I look up to install them I get dizzy. It's been my only major stumbling block for me as of late.

- Messages

- 11,081

- Reactions

- 50,429

Thanks, it has been an experience that's for sure.

Anyone know someone that has crown molding installation experience in the Olympia area?

I have the pieces cut to length but every time I look up to install them I get dizzy. It's been my only major stumbling block for me as of late.

Damn brother I can but finding the time to come up my be another story. Let me see what is on the schedule.

Bronze Supporter

- Messages

- 19,697

- Reactions

- 54,987

I found a local handyman that can help me out but appreciate the offer.

- Messages

- 5,152

- Reactions

- 11,450

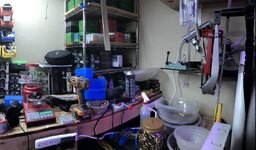

messy? MESSY???? Well it's a start.....

I had to start piling my stuff in a mound because I couldn't remember which little organizer box it was supposed to be in.....

but congratulations on the start of 'getting it all together'.....

I had to start piling my stuff in a mound because I couldn't remember which little organizer box it was supposed to be in.....

but congratulations on the start of 'getting it all together'.....

Bronze Supporter

- Messages

- 19,697

- Reactions

- 54,987

You two! (@Caveman Jim & @Benchrest )

View attachment 276460

need to lay off the sauce!

Btw: there are no 2x4's here. All 4x4's.

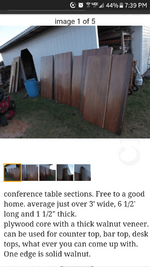

Well I'm digging up this old thread because I am to the point to where I need to Bubble Gum or get off the pot with my bench design. As you can see I am lacking a reloading space no, but I can sure put together guns with this setup.

Four by fours all around you say.... seeing as my bench is going to be 9 ft long I might as well try and get the straightest boards I can get but I probably won't go with four by fours for the horizontal brace. I'm thinking 2X6 for the top brace because I have the benchtop which is inch and 1/2 plywood with a nice stain and polyurethane finish.

Last Edited:

Member 5605

- Messages

- 11,671

- Reactions

- 23,700

NiceWell I'm digging up this old thread because I am to the point to where I need to Bubble Gum or get off the pot with my bench design. As you can see I am lacking a reloading space no, but I can share put together guns with this setup.

Four by fours all around you say.... see until my bench is going to be 9 ft long I might as well try and get the straightest boards I can get but I probably won't go with four by fours for the horizontal brace. I'm thinking 2X6 for the top brace because I have the benchtop which is inch and 1/2 plywood with a nice stain and polyurethane finish.

View attachment 571634

Rip those to 2' wide and have a blast!!!!

- Messages

- 11,081

- Reactions

- 50,429

Those will make a great bench @Caveman Jim!!! Nice find!

Bronze Supporter

- Messages

- 19,697

- Reactions

- 54,987

Those will make a great bench @Caveman Jim!!! Nice find!

thanks, I'm always looking for deals on things that I really need & some things that catch my eye...

Fire bad, tree pretty...

- Messages

- 11,081

- Reactions

- 50,429

thanks, I'm always looking for deals on things that I really need & some things that catch my eye...

Fire bad, tree pretty...

Let me know when your coming down I still have those bins for you brother!

Share This Discussion

Similar threads

- Replies

- 17

- Views

- 425

Upcoming Events

New Classified Ads

-

Henry Golden Boy Silver 22S/L/LR Trade Alert!

- Started by oregontrail113

- Replies: 0

-

Mossberg 590 Shockwave 12ga or Other Brands like this one

- Started by fredball

- Replies: 0

-

-

-

-

Russian makarov pistol IMEZ comes with box and parts kit ammo

- Started by alelord

- Replies: 0

-

WTB or trade for KNS Stock Adapter (AR/MCX) 1913 Picatiny WITH FLANGE

- Started by Jcon268

- Replies: 0

-

-

-

Support Our Community

If our Supporting Vendors don't have what you're looking for, use these links before making a purchase and we will receive a small percentage of the sale