- Messages

- 6,824

- Reactions

- 17,613

- Thread Starter

- #101

PM me an address i will ship you some 38s if need be.

Appreciated, but I'm good -- I haven't been to the range in a month so making some empties sounds like a treat. ;-)

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

PM me an address i will ship you some 38s if need be.

... And a better way to separate anvils and cups. Or make them.

Some time ago I was thinking about cups and started with whether I could find material. I measured the Federal SPP cup material at 0.4 mm which is 0.01575" thick. This measurement was with calipers not a micrometer so I wouldn't think it is accurate 5 decimal places and because there is a flat side to a caliper prong, and I was measuring a round wall, my measurement could be a little bit over the actual thickness.

Anyway, material. Easy to get 0.015" brass sheets which are probably close enough: https://www.amazon.com/Sheet-10-0-015-Brass/dp/B0006N6WJE

In my mind I can envision a die set with a dimple in one half and a prod in the other (I don't know what the real words should be for this type of device) squeezing sheet brass into a cup. What I can't envision because I have no experience with this sort of thing, is a good way to cut the cup out of the sheet. Maybe somebody here has ideas for that?

EDIT: or maybe, you cut a disc first and then form?

EDIT: I was meaning to quote this when I posted the above:

How about a die that forms and cuts at the same time? You need one size that could mount and work in a standard loading press for the single stage guys and another that would work in a Harbor Freight hydraulic style press for higher volumes.

Something on the lines of a gas check maker should work. One cuts the disk, another die forms the cup. Easy peasy.

I think the white is a protective coating and there might be brown (the good stuff) underneath. The prime-all kits seem like a much better source of the good stuff.Maybe try these, I remember as a kid the white compound came out fairly easy.

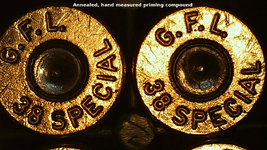

View attachment 799604

I think the white is a protective coating and there might be brown (the good stuff) underneath. The prime-all kits seem like a much better source of the good stuff.

The 22 reloader guy said a bag of theirs would load about 2000 primers or 22 cases.TLDR: The primer recharging packs are a better deal than caps and easier I think because you don't have to disassemble anything to get priming compound. If I was going to dissemble anything for priming compound, I'd take apart 209 shotgun primers or .50 BMG primers, both of which are available for order if you look around.

------------

I paid $20 for the package I bought and I think the .22 reloader brand is similar in price (or was last time I looked). Including bags and stickers minus a single 6.42 grain batch measured according to instructions, I have 980 gr of material left. If these work OK at 0.20 gr per primer, that would be enough stuff to make 4900 primers. That seems like a lot of primers and is making me think I should have used more compound but I used the amount described in the instructions (1/3 of the small measure which weighed out to 0.20 gr).

Theoretically, my first 6.42 grain batch should be enough for 32 primers but I had some waste in transferring from mixing surfaces and spillage (it ain't easy pouring powder into a primer cup) but even with those losses, I had enough for 20 (17 completed, one popped to test if it would go bang, two weight tests, and enough residue to scrape up another primer).

If I only manage 20/32 efficiency, I should get 4900*0.625 primers, or about 3000 primers, which works out to 2/3 of a cent each.

Caps:

192 for 6.98, 3.6c each (assuming one is enough): https://www.tintoyarcade.com/super-bang-ring-caps-refill-192-shots.html?search=caps&description=true

The 22 reloader guy said a bag of theirs would load about 2000 primers or 22 cases.

| A | B | C | D | E |

1 | 868 | 850 | | 740 | 634 |

2 | | 840 | 939 | 598 | |

3 | 872 | 826 | 911 | 714 | 805 |

4 | 906 | 772 | 872 | 752 | 794 |

5 | 884 | 823 | 908 | 529 | 655 |

6 | 860 | 849 | | 740 | 816 |

7 | 839 | 857 | 905 | 770 | 797 |

8 | | 853 | 897 | 780 | 750 |

ES | 67 | 85 | 67 | 251 | 182 |

AVG | 871.5 | 833.8 | 905.3 | 702.9 | 750.1 |

SD | 22.6 | 27.9 | 21.7 | 90.2 | 75.3 |