- Messages

- 5,152

- Reactions

- 11,450

as "NOT" a machinist, this seems like contradictoryredesigning of the primer could be made to make it easier to build. I'm thinking creating a small lip on the cup bent inwards.

goals; please clarify.

goals; please clarify.Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

as "NOT" a machinist, this seems like contradictoryredesigning of the primer could be made to make it easier to build. I'm thinking creating a small lip on the cup bent inwards.

goals; please clarify.

goals; please clarify.I tried using them to wet tumble. Never would have guessed so many would re-seat themselves so perfectly back into the primer pockets!As far as hardening of the cups, an anneal cycle would remedy that.

I have about 10# of spent primers in a jar. By accident, found they actually work pretty good in a wet tumble. It sure cleans the primers and anvils too!

Buddy did an automation project at a munitions factory, I think in MT. They hand filled artillery shell primers with priming compound in an explosion proof room, kept at 35°F. It was called "The Boom Tomb".

Just as an aid in inserting and keeping the anvil in place.as "NOT" a machinist, this seems like contradictorygoals; please clarify.

What about strike anywhere matches, like mentioned in the homemade primer course?And that's it. Nothing else shows up in my search. It's kind of worrisome that toy caps are disappearing.

About ten minutes into futzing with the anvil and trying to take measurements, I realized why Berdan primers exist! Those would be a snap to recharge.

Right up until you run out of primers!Having reloaded Berdan primed cases in the early 2000's after exhausting all my Berdan primers I promised myself I would never engage in masochism again.. Using a Lachmiller tool to decap the brass works but it is tedious and slow the hydraulic method is slightly easier but you end up getting wet. There is just no easy and clean way to do it. Boxer primers were truly God's gift to shooters and further proof he loves us.

Right up until you run out of primers!

Guess I should start scrounging up all of the 303 British Berdan crap I have.

Dad, never a reloader, taught me the difference when I was young (he taught me lots of good things. I'm very lucky) I always "knew" the Boxer was better, until it's time to recharge primers. I do have a few rolls of caps left...

...

Oh, and as for putting a lip around the edge to hold the anvil.. it shouldn't be too difficult to burnish an edge on the brass cup like is done for a woodworking scraper.. just difficult to do it in the full circle.

Lame -- the brushes in my router just gave up the ghost midway through a cut and the last time I replaced them I forgot to order more. So I'm down until the weekend considering tomorrow is a holiday -- but I have to make pies anyway. ;-)

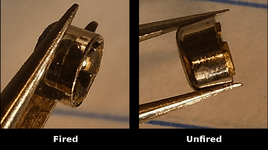

Are the primer anvils distorted by the previous firing?

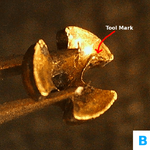

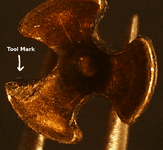

Up NextRemoving Anvils

Wet tumbling primers with brass and pins failed. Getting the anvils out by holding the primer with tweezers or pliers is very hard. I have the first primer cup plate -- the one that didn't fit the base -- and I thought I'd try using that to hold the spent primers. I filed a glasses screwdriver to fit in the anvil windows -- I already ruined a pair of tweezers using them to pry with. It works OK -- still sort of slow but I suspect that with practice I could get about 100 done in 30 minutes, which isn't the end of the world. One trick when prying the anvils loose, don't aim toward the center of the primer with the prying force -- they often pop and melt into the concrete floor. Applying force parallel to the circle though, tends to cause them to roll, and then they can be picked out easily.