- Messages

- 6,824

- Reactions

- 17,613

- Thread Starter

- #81

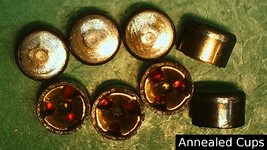

... Fail strength should be significantly more than torque spec. ...

I'm getting to know what that feels like -- something different than the bolt scrinching into threads -- like it slowly becomes pasta, then twists easily and the head pops off. It's sorta fun.