Navigation

Install the NWFA app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More Options

You are using an outdated browser

The browser you are using is likely incompatible with our website. We recommend upgrading your current browser or installing an alternative.

JavaScript is disabled

Our website requires JavaScript to function properly. For a better experience, please enable JavaScript in your browser settings before proceeding.

-

Join the #1 community for gun owners of the Northwest

We believe the 2nd Amendment is best defended through grass-roots organization, education, and advocacy centered around individual gun owners. It is our mission to encourage, organize, and support these efforts throughout Oregon, Washington, Idaho, Montana, and Wyoming.Free Membership Benefits

- Fewer banner ads

- Buy, sell, and trade in our classified section

- Discuss firearms and all aspects of firearm ownership

- Join others in organizing against anti-gun legislation

- Find nearby gun shops, ranges, training, and other resources

- Discover free outdoor shooting areas

- Stay up to date on firearm-related events

- Share photos and video with other members

- ...and much more!

- Messages

- 2,499

- Reactions

- 5,708

In my experience it depends on how you apply it (method and amount) and humidity and it can vary a little with the shake and bake method. I usually see a .002-.004 increase in diameter at 50 to 60% humidity. I usually run them through a lee sizer to make them consistently sized. It really doesn't take long once you get rolling and perfect your method. I do batches of 150 in the toaster oven and by the time one batch is cooked the next is ready to go in. I can do about 3 batches per hour. I haven't seen accuracy issues from slightly different thicknesses in pistol and revolver. The coating is tough and hard but not brittle.So.... How do you control how much is applied? Seems there's a pretty tight tolerance on the diameter of a bullet being squeezed down the bore of a barrel.

Seems there'd be un-uniform thickness at different locations around the bullet diameter.

How much thickness does it add?

You can see in the pic above that it ingraves nicely in the barrel without srtipping off.

Last Edited:

Bronze Supporter

- Messages

- 563

- Reactions

- 665

Hi-tech is a liquid and if you weigh your batches of bullets you can use a syringe type medicine dropper to measure very precisely how much you add 6cc to 5 lbs adds about 1/2 a thousandth to bullet diameter per coat. I size before the final coat and have pretty good results.

Didn't realize the bullet could be sized afterward. Figured it would shave off the coating. Makes more sense now.In my experience it depends on how you apply it (method and amount) and humidity and it can vary a little with the shake and bake method. I usually see a .002-.004 increase in diameter at 50 to 60% humidity. I usually run them through a lee sizer to make them consistently sized. It really doesn't take long once you get rolling and perfect your method. I do batches of 150 in the toaster oven and by the time one batch is cooked the next is ready to go in. I can do about 3 batches per hour. I haven't seen accuracy issues from slightly different thicknesses in pistol and revolver. The coating is tough and hard but not brittle.

View attachment 429516

You can see in the pic above that it ingraves nicely in the barrel without srtipping off.

- Messages

- 2,499

- Reactions

- 5,708

I can size a properly cured .358 that is pc'd up to .361 down to .352 in 2 steps and it just moves right with the lead. It's fascinating really. It's amazing stuff.Didn't realize the bullet could be sized afterward. Figured it would shave off the coating. Makes more sense now.

Gold Supporter

Bronze Supporter

- Messages

- 24,897

- Reactions

- 59,256

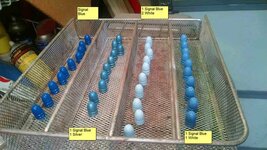

The sate of California has banned orange and blue.. so they got that going on..Someone has to figure out how to screen print cool designs on "evil" bullets:

View attachment 429276

lol jk

Gold Supporter

- Messages

- 714

- Reactions

- 737

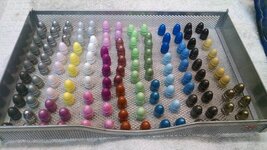

Those look good! I've not seen anything like that sold in stores or on line. I'd like to buy some from you for my 45-70 if you can make them in .459 diameter? Let me know if that is possible? Also what bullet choices (weight and shape) can you cast and powder coat for the 45-70?(pictures?) Thanks in advanceSome of the colors I have

PC before baking

View attachment 430611

PC after baking

View attachment 430612

new 45/70 500 grn mold

View attachment 430613

Max

Silver Supporter

- Messages

- 2,021

- Reactions

- 2,727

I do like the looks of those!

- Messages

- 2,628

- Reactions

- 4,001

Perhaps I missed it earlier ... where are you getting the coatings in all of these colors?

- Messages

- 1,847

- Reactions

- 2,420

- Messages

- 1,562

- Reactions

- 2,715

I like all the colors haha mine are all just blue

Share This Discussion

Similar threads

Upcoming Events

Support Our Community

If our Supporting Vendors don't have what you're looking for, use these links before making a purchase and we will receive a small percentage of the sale