Bronze Supporter

- Messages

- 624

- Reactions

- 778

So I just went up and checked out my new silencer at the FFL and when we went to put the QD muzzle brake on we noticed it was really loose and sloppy on the threads. It did tighten up nice on the shoulder and was perfectly concentric with the bore. I gave it 30ft-lbs and we fired 10-15 rounds to check function. It didn't back off or anything.

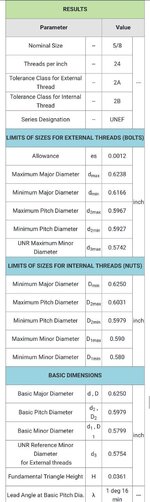

We measured the threads and the tops of the threads measure .612 and the chart he had said 5/8x24 is supposed to be .625, so it's a bit small.

We are concerned that if it does come loose it will be sloppy enough to cause baffle strikes.

So my question is will rocksett and a little extra torque be enough to hold it or will there be issues? Will the extra gap be a problem for the rocksett? Should I use a different host or get a new barrel?

We measured the threads and the tops of the threads measure .612 and the chart he had said 5/8x24 is supposed to be .625, so it's a bit small.

We are concerned that if it does come loose it will be sloppy enough to cause baffle strikes.

So my question is will rocksett and a little extra torque be enough to hold it or will there be issues? Will the extra gap be a problem for the rocksett? Should I use a different host or get a new barrel?