Bronze Supporter

- Messages

- 16,080

- Reactions

- 33,983

So... my Singer Heavy Duty 4411 seems to not want to cooperate with the #69 bonded nylon thread and 420D uncoated Nylon fabrics... the symptoms are basically...

Bobbin thread not getting pulled into lock stitch

With 2 layers of webbing on top of nylon fabric, presser foot down, I get gnarly loops

If I flip so that fabric is on top.of 2 layers, little better but I can see knots/loops from top thread..

Bobbin thread just "lays" there, with a seam ripper, I can easily pull it out like a basting stitch.

Fresh #16 and #18 needles tried.

Checked tension dial

Rethreaded machine with tension set to 0

Tension cranked to 7 to 9 depending on how big loops look..

Bobbin tension left alone, did adjust last night, no change in actual stitches...

So.

The machine in question.

Scrap. Coyote thread was bobbin thread, same size. Smaller stitches from Riccar 2925 school machine.

Underside and showing loops from 2 layers of webbing on top, and flipped around.

I have a Singer 15-91 that's awaiting some parts but.. if it doesn't do what I need it to do... even though in theory its supposed to be strong enough... being mostly steel gears with a bakelite gear on the handwheel... I'll have to sell it and look at getting something like what's available from Sailrite.. OR find a decent reputation Industrial Sewing Machine... like a Singer 20U series, a Read's Sailmaker, a Juki, Brothers, or older Consew machines... I don't know. Getting annoyed with stitch quality resembling Chineseeium more than Armani.

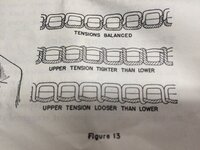

Edit. Diagram added of what balanced stitches should look like

Right now mine looks just like "upper tension looser than lower"

Bobbin thread not getting pulled into lock stitch

With 2 layers of webbing on top of nylon fabric, presser foot down, I get gnarly loops

If I flip so that fabric is on top.of 2 layers, little better but I can see knots/loops from top thread..

Bobbin thread just "lays" there, with a seam ripper, I can easily pull it out like a basting stitch.

Fresh #16 and #18 needles tried.

Checked tension dial

Rethreaded machine with tension set to 0

Tension cranked to 7 to 9 depending on how big loops look..

Bobbin tension left alone, did adjust last night, no change in actual stitches...

So.

The machine in question.

Scrap. Coyote thread was bobbin thread, same size. Smaller stitches from Riccar 2925 school machine.

Underside and showing loops from 2 layers of webbing on top, and flipped around.

I have a Singer 15-91 that's awaiting some parts but.. if it doesn't do what I need it to do... even though in theory its supposed to be strong enough... being mostly steel gears with a bakelite gear on the handwheel... I'll have to sell it and look at getting something like what's available from Sailrite.. OR find a decent reputation Industrial Sewing Machine... like a Singer 20U series, a Read's Sailmaker, a Juki, Brothers, or older Consew machines... I don't know. Getting annoyed with stitch quality resembling Chineseeium more than Armani.

Edit. Diagram added of what balanced stitches should look like

Right now mine looks just like "upper tension looser than lower"