Gold Supporter

Bronze Supporter

- Messages

- 24,873

- Reactions

- 59,172

As was said about five times, yes you do, pretty much. The chamber of your rifle will tell you if it will chamber in your rifle.I don't have a case Guage..

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

As was said about five times, yes you do, pretty much. The chamber of your rifle will tell you if it will chamber in your rifle.I don't have a case Guage..

As was said about five times, yes you do, pretty much. The chamber of your rifle will tell you if it will chamber in your rifle.

... I loaded a few of them up and shot them for accuracy. They all went off and accuracy was normal. I'm not recommending it or even saying I would do it again, just that it worked for me. ...

Also, I didn't use any polish, just the crushed walnut.

I plan to load up about 50 of these and firing them as a test, before doing the rest of the work, ensuring the primers are good.

I don't know what type of rifle you have. If it's a repeater or semiautomatic, feeding empties through the mechanism might prove problematic so you'd drop the case or loaded round directly into the chamber and then close the bolt.Excuse the novice question, you mean load up some of the cases in a mag and see if they'll hand cycle without getting stuck or FTE?

in terms of head space, you can try to chamber unloaded brass and determine if the bolt closes and you can pull the trigger. Much easier with a bolt but certainly viable to a point with a semi auto. Your rifle's chamber is like a go/no go chamber gauge where an actual chamber gauge will give some size info.Excuse the novice question, you mean load up some of the cases in a mag and see if they'll hand cycle without getting stuck or FTE?

I bet a .22lr would chamber too. Doesn't mean it's right or safe.And then after checking all the measurements in the world with gauges and comparators, you still have to see if it'll chamber in your rifle.

You got me there.I bet a .22lr would chamber too. Doesn't mean it's right or safe.

For a target rifle, and that rifle only, I agree.@Certaindeaf has a very valid point, you ultimately need to check your reloads in the firearms chamber but there are some limitations that need to be addressed.

To really use the chamber as a headspace gauge you need to remove the ejector and possible the extractor from the bolt. Anything that places tension on the case or keeps it from moving will interfere with your measurements. With a stripped bolt you can resize bit by bit until you get no resistance to the locking lugs engaging with very light finger pressure. It works great and is very accurate. But it's a chore to strip and reassemble the bolt and on self-feeders like the AR can be very difficult to gently put the bolt home without jogging something causing an inaccurate measurement.

So a dedicate gauge is worth the $14 bucks or so in my mind. You can quickly and safely gauge both cases and loaded rounds with one, and do it will sitting on your behind watching TV.

The Hornady gauges are very good to have as well. These allow you to choose more closely the shoulder set back you desire because you measure it directly rather than trying to use the depth rod on a caliper when using a dedicated case gauge. They also are useful for setting bullet jump and measuring throat erosion.

So once again … as I spend OP's money … get them both!

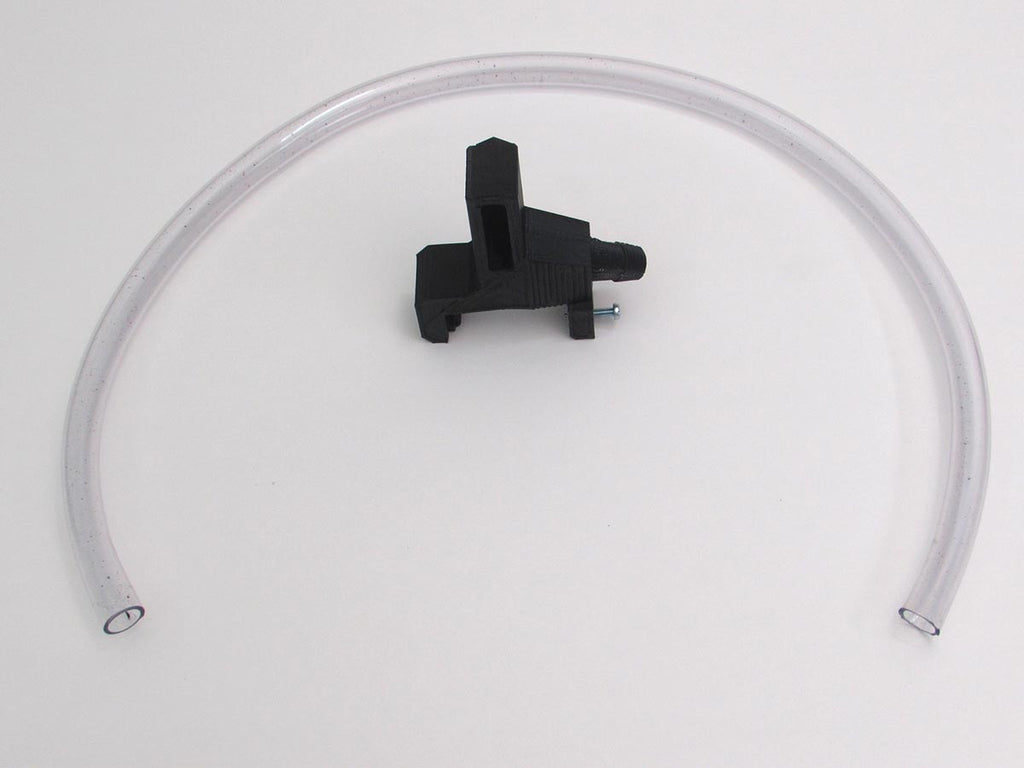

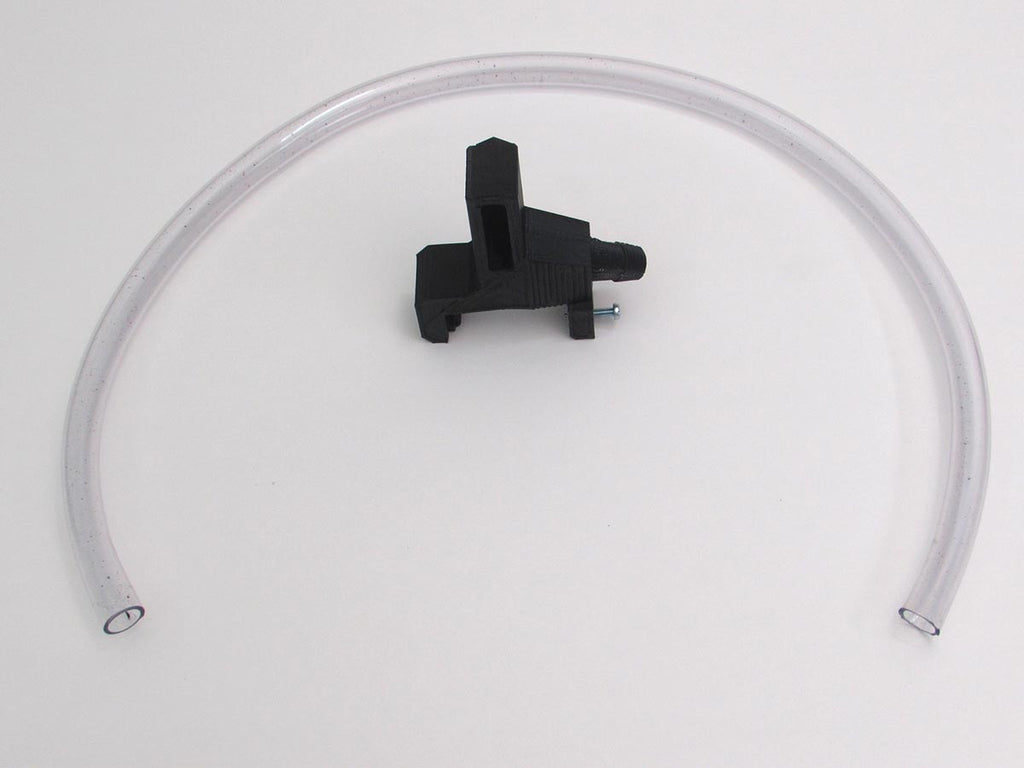

So you disassemble the press to install? Is this correct?Here's the link to the spent primer catching system I mentioned earlier. This is for the Rock Chucker Supreme. I have an RC II so the device is a bit different, but I can't imagine it does not work as well, especially when reading the reviews. It consists of a 3-D printed plastic part that attaches behind the ram and a tube. Bone head simple. You need to turn your ram around to the rear so the primer arm slot faces backward. The spent primer drops down that slot and into the catcher / deflector device and then down the tube to wherever you direct it to go.

On my press, this misses maybe two or three per THOUSAND decapped primers … it's that good! For years I have jury-rigged many different methods to keep from spilling primers all over the floor and bench, with little success except for a big box system that got in the way and stuck out all over the place. This is an elegant solution and anybody who has a single stage press used for de-priming should take a look at Inline's offerings. (no I don't work there!)

The only down-side is you can not use the on press priming system … but who does that with the many inexpensive priming tools available that do a far better job?

Here's the link:

Improved primer catch for RCBS Rockchucker Supreme IV. - Inline Fabrication

The factory primer catch tray for the Rockchucker Supreme can be hit and miss with catching the decapped primers with them...inlinefabrication.com

I'd look at the case ejector they sell as well. I have an original RCBS Case Kicker (no longer in production) and it saves a ton of time on a single stage press, an the Inline version would work even better as it's out of the way while you are putting cases into the shell holder.

Oh yes, this is a local guy as well if that matters to you … he's out of Eugene.

So you disassemble the press to install? Is this correct?