- Messages

- 23

- Reactions

- 32

I'd wanted to get into woodworking for this and other reasons for a while. While hefting a 10/22 at bi-mart because of how I hate the factory stock on my ar-7, I decided that money would be better spent on woodworking tools and some wood to learn the basics.

For my first attempt, I just went with a fir 2x6, since this is just a .22 and I'm bound to make all sorts of first-timer mistakes - rather make them on $3 of cheap wood than a $50 walnut blank.

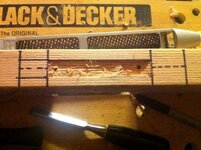

I figured I'd inlet it before anything else, while the wood was still nice and square and easy to clamp in place for working. However, opening up the bottom to make sure the trigger was accessible seemed like a good idea. Doing this, I learned how worthless the coping saw I'd bought was.

I lined out the rough dimensions of the action where I wanted it, and proceeded with the 1/2" wood chisel.

This is a fairly easy gun to inlet for, since the receiver is pretty much a rectangle.

Next, I cut out the forestock. I did this with a hand saw and regretted it. Before doing any more cuts, I went and got a jigsaw.

After getting the jigsaw, I cut out the butt and grip area and worked it a bit with the rasps.

After that, it's just been rasp, chisel, sand to get the shape I want.

Lot of trial and error, and I messed up the tip badly enough to have to cut it off and redo it, twice, but I like how it looks now. This is the stock as of when I retired this evening:

The plan is to repeat the process on a real rifle stock blank once I've gotten enough practice on this one. I know it's a goofy gun to be making a stock for, but eh. All my nicer guns already HAVE good stocks on them :v

For my first attempt, I just went with a fir 2x6, since this is just a .22 and I'm bound to make all sorts of first-timer mistakes - rather make them on $3 of cheap wood than a $50 walnut blank.

I figured I'd inlet it before anything else, while the wood was still nice and square and easy to clamp in place for working. However, opening up the bottom to make sure the trigger was accessible seemed like a good idea. Doing this, I learned how worthless the coping saw I'd bought was.

I lined out the rough dimensions of the action where I wanted it, and proceeded with the 1/2" wood chisel.

This is a fairly easy gun to inlet for, since the receiver is pretty much a rectangle.

Next, I cut out the forestock. I did this with a hand saw and regretted it. Before doing any more cuts, I went and got a jigsaw.

After getting the jigsaw, I cut out the butt and grip area and worked it a bit with the rasps.

After that, it's just been rasp, chisel, sand to get the shape I want.

Lot of trial and error, and I messed up the tip badly enough to have to cut it off and redo it, twice, but I like how it looks now. This is the stock as of when I retired this evening:

The plan is to repeat the process on a real rifle stock blank once I've gotten enough practice on this one. I know it's a goofy gun to be making a stock for, but eh. All my nicer guns already HAVE good stocks on them :v