- Messages

- 154

- Reactions

- 225

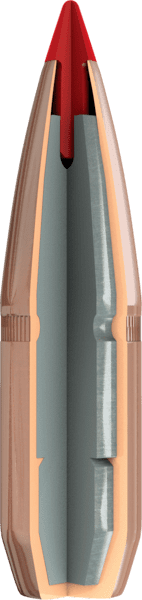

I just recently started reloading. My first loads I am work on are for a 7mm Rem Mag and .338 Win Mag. I decided to go with 162gr SST for the 7mm and 225gr SST for the .338. I picked these because both rifles liked and shot Hornady SST's very well. I measured the bullet seating depth 4 or 5 times and felt good with the measurement I was getting and then decreased it by .022 and went with that. What i don't understand is why manufacturers make bullets with that ribbed ring around the bullet if your not going to seat it deep enough to get into it and does it effect anything by not seating it that deep. I am only asking because when compared to the factory Hornady SST load the bullet is seated just above the ring. It would seem the ring is there to allow better grip between the bullet and case. What's you thoughts? Thanks for any advise.

I am blown away by how much the factory load jump before hitting the lands compared to the reloads I worked up. The .338 is a Savage 116 Bear Hunter. Honestly I am kind of scared to shoot the loads...lol I think the first shot will go in the lead sled with a string on the trigger! It wouldn't be the first time I have done that (crazy old rifles and unknown AR builds, etc)

I am blown away by how much the factory load jump before hitting the lands compared to the reloads I worked up. The .338 is a Savage 116 Bear Hunter. Honestly I am kind of scared to shoot the loads...lol I think the first shot will go in the lead sled with a string on the trigger! It wouldn't be the first time I have done that (crazy old rifles and unknown AR builds, etc)