Gold Supporter

Silver Supporter

Bronze Supporter

- Messages

- 1,099

- Reactions

- 2,075

Disclaimer: I also didn't/don't see the see benefits of annealing, but I bought it anyway.

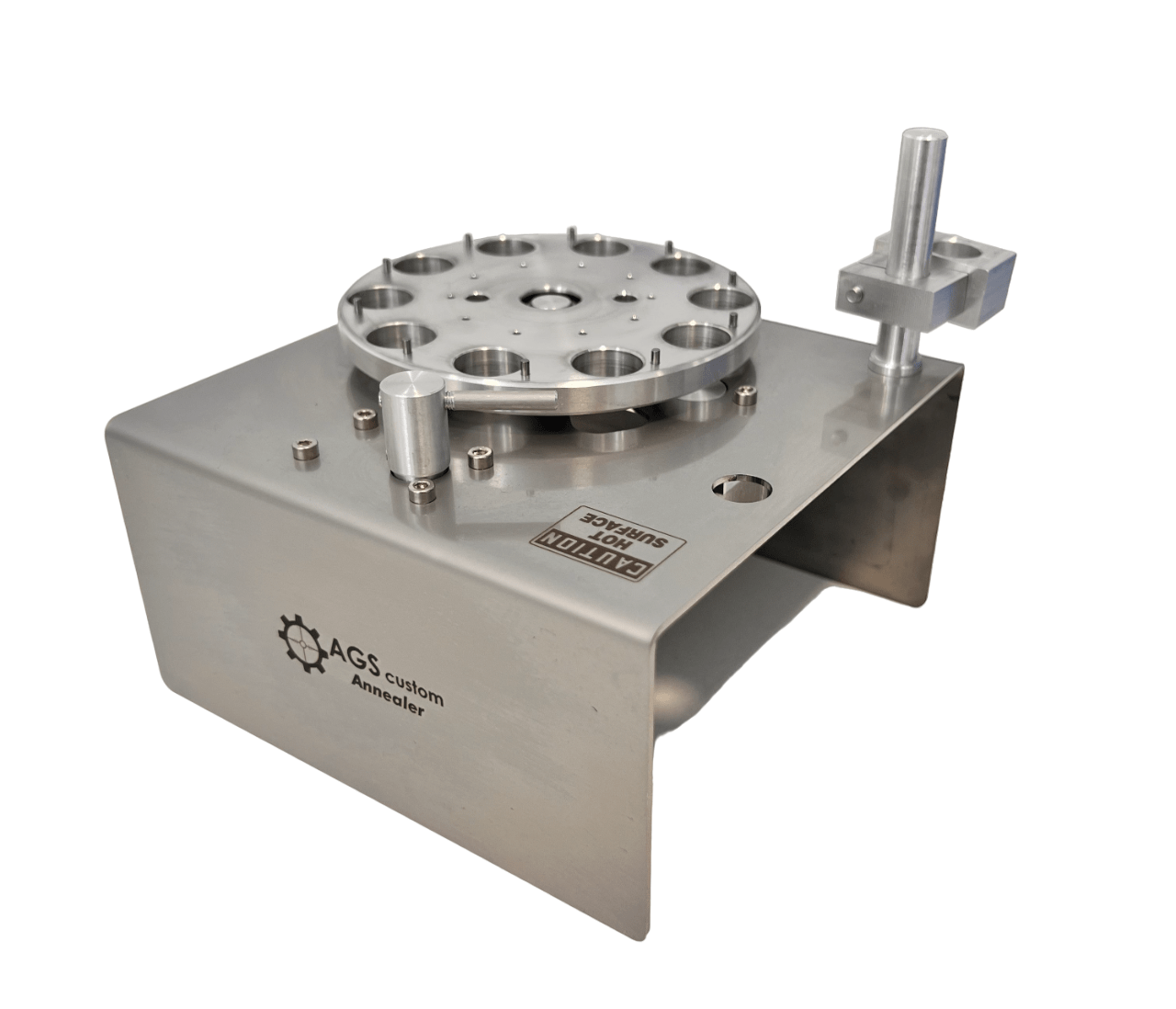

I have been tossing the annealing idea around for a few years now, but could never get past the "do I really need it" question. Well last week I was looking at all of the options for machines again when I came across this model made by Mike's Reloading Bench and I twitched a little (I put a link to his machine below). It has everything I was looking for which is all metal, no changing wheels to change calibers, a hopper and no fancy gauges. The case release flapper was originally operated by apposing magnets, but they took too much abuse from the torch heat and he switched to a cam drive. It is more expensive then the Annealeez, or the small turn table model made by AGS Custom Parts, but the operation and quality are much worth it to me. Also, it showed up today in a very heavy duty box with the machine suspended in poly foam like computers.

My goal with annealing is extending brass life on range fodder like .223, 300 BLK , 6.8 spc. and 30-30, and then experiment with my "rat" loads for the the .223 and .222 just to see what changes if anything. I won't mess with the 30.06 and 8mm since what I have worked up now are in 1x or 2x shot cases and all shoot 1/2"ish groups. With four rifles it took me awhile to get there and I don't want to bubblegum with it LOL. I look forward to the curve.

Does not come with the torch

I have been tossing the annealing idea around for a few years now, but could never get past the "do I really need it" question. Well last week I was looking at all of the options for machines again when I came across this model made by Mike's Reloading Bench and I twitched a little (I put a link to his machine below). It has everything I was looking for which is all metal, no changing wheels to change calibers, a hopper and no fancy gauges. The case release flapper was originally operated by apposing magnets, but they took too much abuse from the torch heat and he switched to a cam drive. It is more expensive then the Annealeez, or the small turn table model made by AGS Custom Parts, but the operation and quality are much worth it to me. Also, it showed up today in a very heavy duty box with the machine suspended in poly foam like computers.

My goal with annealing is extending brass life on range fodder like .223, 300 BLK , 6.8 spc. and 30-30, and then experiment with my "rat" loads for the the .223 and .222 just to see what changes if anything. I won't mess with the 30.06 and 8mm since what I have worked up now are in 1x or 2x shot cases and all shoot 1/2"ish groups. With four rifles it took me awhile to get there and I don't want to bubblegum with it LOL. I look forward to the curve.

Does not come with the torch