I'm just wondering if anyone knows what salts are used in the molten salt method for bluing small steel parts, and if ordering them will get me on a watch list? I was going to buy a ten pound bucket from Brownell's of their "NitreBlue" but it's on back order. I have an old Lee lead pot that I don't use anymore because it's too small... figured it would work well for bluing.

Navigation

Install the NWFA app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More Options

You are using an outdated browser

The browser you are using is likely incompatible with our website. We recommend upgrading your current browser or installing an alternative.

JavaScript is disabled

Our website requires JavaScript to function properly. For a better experience, please enable JavaScript in your browser settings before proceeding.

-

Join the #1 community for gun owners of the Northwest

We believe the 2nd Amendment is best defended through grass-roots organization, education, and advocacy centered around individual gun owners. It is our mission to encourage, organize, and support these efforts throughout Oregon, Washington, Idaho, Montana, and Wyoming.Free Membership Benefits

- Fewer banner ads

- Buy, sell, and trade in our classified section

- Discuss firearms and all aspects of firearm ownership

- Join others in organizing against anti-gun legislation

- Find nearby gun shops, ranges, training, and other resources

- Discover free outdoor shooting areas

- Stay up to date on firearm-related events

- Share photos and video with other members

- ...and much more!

- Messages

- 8

- Reactions

- 1

I am looking for same info. Found a how to do it yourself online but not sure how to get ingredients. In western WashingtonI'm just wondering if anyone knows what salts are used in the molten salt method for bluing small steel parts, and if ordering them will get me on a watch list? I was going to buy a ten pound bucket from Brownell's of their "NitreBlue" but it's on back order. I have an old Lee lead pot that I don't use anymore because it's too small... figured it would work well for bluing.

Gold Supporter

Bronze Supporter

- Messages

- 3,565

- Reactions

- 12,052

Get yourself a copy of Firearms Blueing and Browning by R.H. Angier. 230 ways to make blueing and browning formulas and everything else you could ever want to know about the process. Originally published in 1936 but I believe there are modern printings available.

- Messages

- 33

- Reactions

- 48

so I have done two types of bluing, the first was just melt around 50lbs of potassium nitrate to 700 ish degrees, and put part in. It works and the items look good, but it's hot, you use a lot of propane, and you can get better results with the second method. Rust blue, Brownells sells it, works great. You end up putting on around 8 coats. My buddy did 13 coats on an AKM reciever, looks super good. Just remember less is more, don't put on a bubblegum ton of the browning compound to hurry things along. You rust it, you boil it, lightly remove rust with 3 aught or 4 aught steel wool (degrease it in solvent of your choice, acetone works great), re-coat, let sit overnight , repeat till desired depth of blueing is achieved, looks better than any hot blue. I first used it on an RPK, I was astonished at how nice it turned out.I'm just wondering if anyone knows what salts are used in the molten salt method for bluing small steel parts, and if ordering them will get me on a watch list? I was going to buy a ten pound bucket from Brownell's of their "NitreBlue" but it's on back order. I have an old Lee lead pot that I don't use anymore because it's too small... figured it would work well for bluing.

- Messages

- 8

- Reactions

- 1

Expensive book on Amazon 95.00Get yourself a copy of Firearms Blueing and Browning by R.H. Angier. 230 ways to make blueing and browning formulas and everything else you could ever want to know about the process. Originally published in 1936 but I believe there are modern printings available.

- Thread Starter

- #7

The book mentioned is pretty inexpensive on kindle, and thanks for the info!

I found potassium nitrate, sodium nitrate, and manganese dioxide on amazon, to try out. Repurposing my old Lee lead pot, and will add a pid controller and thermocouple to precisely control the heat.

While this will be handy for doing small parts for guns, like screws, the main purpose is to provide a finish for art medallions I'm doing on the cnc mill.

On the watchlist issue, it's Ammonium nitrate that was used as an explosive. ( not needed for bluing) The other chemicals all have many uses and are widely available without a lot of unwanted scrutiny from three letter agencies.

If I were bluing a gun, I expect I would use the more durable rust bluing methods, but I just wanted to figure out nitre bluing for small stuff, because it's fast and low effort. Here is an overview with good info: https://tincanbandit.blogspot.com/2014/06/nitre-bluing.html

I found potassium nitrate, sodium nitrate, and manganese dioxide on amazon, to try out. Repurposing my old Lee lead pot, and will add a pid controller and thermocouple to precisely control the heat.

While this will be handy for doing small parts for guns, like screws, the main purpose is to provide a finish for art medallions I'm doing on the cnc mill.

On the watchlist issue, it's Ammonium nitrate that was used as an explosive. ( not needed for bluing) The other chemicals all have many uses and are widely available without a lot of unwanted scrutiny from three letter agencies.

If I were bluing a gun, I expect I would use the more durable rust bluing methods, but I just wanted to figure out nitre bluing for small stuff, because it's fast and low effort. Here is an overview with good info: https://tincanbandit.blogspot.com/2014/06/nitre-bluing.html

- Messages

- 783

- Reactions

- 511

What is "K" on the periodic table of elements? I think you are mixing your elements up compared to the formulasHere are places to get Kno3. Ammonium nitrate (salts). Try instant coldpacks but check ingredients before buying. Stump remover could be 90%. I have seen bags of it in grocery stores for curing food. Their is a method to get it from dirt also.

Bronze Supporter

- Messages

- 16,789

- Reactions

- 27,563

And......I just happened to run across this the other day.

Aloha, Mark

Aloha, Mark

- Messages

- 5,367

- Reactions

- 7,749

The hard part with nitre bluing isn't the bluing or getting the materials, it's proper metal prep. For best results, the small parts need to be polished to a matchless finish. That takes time, effort, and equipment.

But if you can do it and do it well, it's hard to beat the finish on small parts.

But if you can do it and do it well, it's hard to beat the finish on small parts.

- Messages

- 33

- Reactions

- 48

+1 on this, just gotta find the mind set to enjoy the time consuming prep and put in the effort.The hard part with nitre bluing isn't the bluing or getting the materials, it's proper metal prep. For best results, the small parts need to be polished to a matchless finish. That takes time, effort, and equipment.

But if you can do it and do it well, it's hard to beat the finish on small parts.

- Messages

- 33

- Reactions

- 48

Cool, looking forward to your report.All chemicals are now here, hoping to have time to set up a pid control on the old Lee pot this weekend, and try it out. ( work today, match tomorrow... )

- Messages

- 428

- Reactions

- 899

- Messages

- 783

- Reactions

- 511

Simply amazing. Great lookI use stump remover found at Home Depot. Same thing as the fancy salts sold by Brownell's. It's simply saltpeter. I do it on the kitchen stove. Proper PPE and ZERO water in the vicinity is a must. As mentioned before, prep is everything. The lead pot is a good idea. I've just never invested in it.

View attachment 849914 View attachment 849915 View attachment 849916 View attachment 849917 View attachment 849919

- Thread Starter

- #16

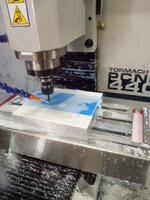

Just a quick project update: got most of the parts in for the pid controller, just waiting on a cord so I can figure out what size holes to put in the back panel, and a 115 vac fan to keep the heat sink under the SSR cool. I have the front panel laid out in cad/cam, going to try the " blue tape and super glue" method of workholding to cut the panel openings on the mill.

I'm pretty impressed with what cool project enclosures are available now for pretty reasonable $.

Might seem like a lot of work to make something like this, but I know if it's built well, I will be able to use it for many years. (It's important to me to understand my tools, and be able to repair them) Making it with a socket for the thermocouple connection, so I can use the same control box for the coating oven (bulletmaking) , the various enameling and bluing operations, and for a future electrically heated 100 lb lead melter, and just have appropriate thermocouples permanently attached to the various things that use them.

If anyone is interested, I can share materials lists/costs/sources, as well as cad drawings and even G-code.

I'm pretty impressed with what cool project enclosures are available now for pretty reasonable $.

Might seem like a lot of work to make something like this, but I know if it's built well, I will be able to use it for many years. (It's important to me to understand my tools, and be able to repair them) Making it with a socket for the thermocouple connection, so I can use the same control box for the coating oven (bulletmaking) , the various enameling and bluing operations, and for a future electrically heated 100 lb lead melter, and just have appropriate thermocouples permanently attached to the various things that use them.

If anyone is interested, I can share materials lists/costs/sources, as well as cad drawings and even G-code.

- Thread Starter

- #17

Progress update...

Used a new method I saw on a NY CNC Youtube video. Mount a semi-sacrificial block on the table, and face it off level, then clean it with isopropyl, and apply blue tape. Clean the back of your stock, in this case, the panel, and apply blue tape. Use super glue ( cyanoacrylate) between the layers of tape to stick the part to the table. They show doing some pretty aggressive cuts on a 3" tall aluminum block held this way, and it stuck just fine.

It worked very well, I'll be using this method again!

Finished panels.

Started the wiring, but found I was missing ring terminals for my chassis ground, and some spades to finish it nicely.

Time to eat pizza and drink beer, will return to this after getting terminals.

Used a new method I saw on a NY CNC Youtube video. Mount a semi-sacrificial block on the table, and face it off level, then clean it with isopropyl, and apply blue tape. Clean the back of your stock, in this case, the panel, and apply blue tape. Use super glue ( cyanoacrylate) between the layers of tape to stick the part to the table. They show doing some pretty aggressive cuts on a 3" tall aluminum block held this way, and it stuck just fine.

It worked very well, I'll be using this method again!

Finished panels.

Started the wiring, but found I was missing ring terminals for my chassis ground, and some spades to finish it nicely.

Time to eat pizza and drink beer, will return to this after getting terminals.

- Messages

- 1,241

- Reactions

- 2,505

Ammonium nitrate has historically been a very common fertilizer. 34-0-0 is it's fertilizer designation. It is a favorite product for blasting when mixed with diesel and is called ANFO. It is also the white granular stuff used in tannerite. Because of government restrictions imposed after the Oklahoma bombings in the last century, it is somewhat harder to procure. However, knowing the right sources, it can be acquired.On the watchlist issue, it's Ammonium nitrate that was used as an explosive. ( not needed for bluing) The other chemicals all have many uses and are widely available without a lot of unwanted scrutiny from three letter agencies.

No wonder I had a weird notion it was used to remove stumps!Ammonium nitrate has historically been a very common fertilizer. 34-0-0 is it's fertilizer designation. It is a favorite product for blasting when mixed with diesel and is called ANFO. It is also the white granular stuff used in tannerite. Because of government restrictions imposed after the Oklahoma bombings in the last century, it is somewhat harder to procure. However, knowing the right sources, it can be acquired.

- Messages

- 2

- Reactions

- 0

Kno3 is potassium nitrate not ammonium nitrate.Here are places to get Kno3. Ammonium nitrate (salts). Try instant coldpacks but check ingredients before buying. Stump remover could be 90%. I have seen bags of it in grocery stores for curing food. Their is a method to get it from dirt also.

Share This Discussion

Similar threads

Upcoming Events

New Classified Ads

-

-

Mitsubishi outlander sports 2014 manual transmission

- Started by jerhine23

- Replies: 0

-

-

-

-

-

-

-

-

Support Our Community

If our Supporting Vendors don't have what you're looking for, use these links before making a purchase and we will receive a small percentage of the sale