Navigation

Install the NWFA app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More Options

You are using an outdated browser

The browser you are using is likely incompatible with our website. We recommend upgrading your current browser or installing an alternative.

JavaScript is disabled

Our website requires JavaScript to function properly. For a better experience, please enable JavaScript in your browser settings before proceeding.

-

Join the #1 community for gun owners of the Northwest

We believe the 2nd Amendment is best defended through grass-roots organization, education, and advocacy centered around individual gun owners. It is our mission to encourage, organize, and support these efforts throughout Oregon, Washington, Idaho, Montana, and Wyoming.Free Membership Benefits

- Fewer banner ads

- Buy, sell, and trade in our classified section

- Discuss firearms and all aspects of firearm ownership

- Join others in organizing against anti-gun legislation

- Find nearby gun shops, ranges, training, and other resources

- Discover free outdoor shooting areas

- Stay up to date on firearm-related events

- Share photos and video with other members

- ...and much more!

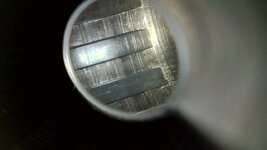

Have you ever seen such poor rifling?

- Thread Starter Sbarton

- Start date

Member 34319

- Messages

- 17,146

- Reactions

- 37,067

My Taurus looks worse!

That is a lot of chatter, but the lands looks pretty decent. Surprised it groups so badly. Sure it isn't just copper fouling?

That is a lot of chatter, but the lands looks pretty decent. Surprised it groups so badly. Sure it isn't just copper fouling?

Silver Lifetime

- Messages

- 744

- Reactions

- 2,362

Wow! That's terrible! It hurts me to know a fellow firearms enthusiast is burdened with such a machine. I'd like to do my part to help. If you send me the rifle, I'll make sure it never bothers you again.

On a more serious note, that's unfortunate. I wonder if a smith could do something like sleeve the barrel or re-barrel it from one that turns up with a damaged receiver or use a blank barrel and fit it to the rifle. Once Ruger finishes spinning up Marlin production, I wonder if they'd be willing to help you out.

Best of luck!

On a more serious note, that's unfortunate. I wonder if a smith could do something like sleeve the barrel or re-barrel it from one that turns up with a damaged receiver or use a blank barrel and fit it to the rifle. Once Ruger finishes spinning up Marlin production, I wonder if they'd be willing to help you out.

Best of luck!

Bronze Supporter

- Messages

- 20,322

- Reactions

- 77,047

Get your self some of the Tubbs 2000 fire lapping bullets, start with the rough grit and shoot your way through to the fine, should tighten it right up for ya!

- Thread Starter

- #5

There's a bit of copper in there, but there was also a bunch of lead, the bore slugged at .431, so it leads up pretty badly, gotta find some bigger bullets.

Trust me, you don't want it!

I may see if i can get a new barrel from ruger, but that's a big question mark right now. I don't think it can be sleeved, it's pretty thin at the muzzle, but i may check around with some gunsmiths, see what they say.

Trust me, you don't want it!

I may see if i can get a new barrel from ruger, but that's a big question mark right now. I don't think it can be sleeved, it's pretty thin at the muzzle, but i may check around with some gunsmiths, see what they say.

- Thread Starter

- #6

I thought about that, never had to do it before.Get your self some of the Tubbs 2000 fire lapping bullets, start with the rough grit and shoot your way through to the fine, should tighten it right up for ya!

Maybe I'll give that a shot.

One thing I do know, it probably couldn't hurt the accuracy. This thing throws bullets everywhere, I wouldn't want to stand next to someone shooting it!

Gold Supporter

- Messages

- 5,622

- Reactions

- 12,005

JB Bore Bright is also a time-honored classic in cleaning up rough bores.

www.brownells.com

www.brownells.com

BROWNELLS J-B® BORE BRIGHT | Brownells

A micro-fine bore cleaning and finishing compound that works as both a cleaner and a final polish to help keep barrels free of fouling and shooting their absolute best. Regular use gives your barrel a mirror-like finish that helps prevent the buil...

Gold Supporter

Bronze Supporter

- Messages

- 24,908

- Reactions

- 59,277

Regular cast slugs should be .430 and very often are bigger if unsized.

Powder coating will make them fatter still.. shoot for .432 at least and it'll probably group fine.

A little JB bore polishing compound wouldn't hurt either. Mind the crown and make sure it's not damaged currently.

Powder coating will make them fatter still.. shoot for .432 at least and it'll probably group fine.

A little JB bore polishing compound wouldn't hurt either. Mind the crown and make sure it's not damaged currently.

Bronze Lifetime

- Messages

- 4,916

- Reactions

- 12,963

Yes, I've seen rifling like that, on a similar vintage Marlin .44 mag. What's worse is the roll stamp on the side of the barrel. You can see dents through to the inside of the bore from the stamps.

I had the same problem with accuracy (or lack thereof). I ended up sizing my cast bullets about .4315", a compromise that also works well in my revolvers, as any bigger didn't seem to make much difference in my rifle. I also found that the magazine tube was binding badly on the barrel and receiver. I relieved that binding and it did make a difference.

It still shoots mediocre with plain base cast bullets. It does much better with gas-check cast, as well as jacketed bullets. It's still no target rifle, but it's at least acceptable now.

I had the same problem with accuracy (or lack thereof). I ended up sizing my cast bullets about .4315", a compromise that also works well in my revolvers, as any bigger didn't seem to make much difference in my rifle. I also found that the magazine tube was binding badly on the barrel and receiver. I relieved that binding and it did make a difference.

It still shoots mediocre with plain base cast bullets. It does much better with gas-check cast, as well as jacketed bullets. It's still no target rifle, but it's at least acceptable now.

- Thread Starter

- #10

Mine, like yours, also has tight spots. I'm looking at lapping the thing. Tubs doesn't sell a .44 cal, but I do have plenty dead soft lead, I'll probably lap it by hand.Yes, I've seen rifling like that, on a similar vintage Marlin .44 mag. What's worse is the roll stamp on the side of the barrel. You can see dents through to the inside of the bore from the stamps.

I had the same problem with accuracy (or lack thereof). I ended up sizing my cast bullets about .4315", a compromise that also works well in my revolvers, as any bigger didn't seem to make much difference in my rifle. I also found that the magazine tube was binding badly on the barrel and receiver. I relieved that binding and it did make a difference.

It still shoots mediocre with plain base cast bullets. It does much better with gas-check cast, as well as jacketed bullets. It's still no target rifle, but it's at least acceptable now.

I'm sorry to hear yours still doesn't shoot well, I think there's a couple things with these .44 marlins that lead to poor accuracy, besides the chatter marks.

Frankly, if I'd have known what a dog this rig would be, I'd have bought a henry instead. The rifling pitch on their new .44 barrels is 1-20, instead of marlin's 1-38.

Thanks everyone for the recommendations, all good information.

I've seen some crappy barrels in handguns made in the past 15 or 20 years. You've got to look at Colt factory barrels very carefully before buying. Also Smith & Wesson revolvers, if you can find one these days. After reading about frequent turnover of $12 an hour employees in gun factories, it shouldn't be surprising. But you pay good money for a quality arm such as a Colt or Smith, you expect better.

The Marlin barrel shown in the OP, not often seen in the 1980's in my limited observation. If anyone at the factory was aware of it, maybe they thought nobody would notice in a Microgroove barrel.

The Marlin barrel shown in the OP, not often seen in the 1980's in my limited observation. If anyone at the factory was aware of it, maybe they thought nobody would notice in a Microgroove barrel.

Bronze Lifetime

- Messages

- 4,916

- Reactions

- 12,963

I probably could have worded my post better. Mine actually shoots pretty decent now with gas check or jacketed bullets, just not as good with plain base. I powder coat too, no leading at all. It's just not a target rifle.Mine, like yours, also has tight spots. I'm looking at lapping the thing. Tubs doesn't sell a .44 cal, but I do have plenty dead soft lead, I'll probably lap it by hand.

I'm sorry to hear yours still doesn't shoot well, I think there's a couple things with these .44 marlins that lead to poor accuracy, besides the chatter marks.

Frankly, if I'd have known what a dog this rig would be, I'd have bought a henry instead. The rifling pitch on their new .44 barrels is 1-20, instead of marlin's 1-38.

Thanks everyone for the recommendations, all good information.

Average accuracy with my favorite load for it, a powder coated 429244, over a full load of H110, was IIRC around 2.5" or 3" at 100 yards. I would get some nice 2" groups, then a flyer that would open it up to 3.5" occasionally. I figure that's decent for what it is. The biggest accuracy improvement came from relieving the mag tube binding.

I've often heard of guys with their tack driving 1moa lever rifles and am seriously impressed by those that can do it, but mine sure won't.

Gold Supporter

- Messages

- 5,622

- Reactions

- 12,005

I have a 444 from about 1978 that was one of the first after Marlin switched from dovetailed front sights to screwed-on sights. They drilled the holes too deep, causing two slight bulges into the bore. Sent it back and they screwed on a new barrel N/C. But that was then, two owners ago.Yes, I've seen rifling like that, on a similar vintage Marlin .44 mag. What's worse is the roll stamp on the side of the barrel. You can see dents through to the inside of the bore from the stamps.

Diamond Supporter

Platinum Supporter

Gold Lifetime

Silver Lifetime

Bronze Lifetime

- Messages

- 3,974

- Reactions

- 9,950

No. Never seen anything like that. I didn't even know rifling could be that bad.Marlin 94, 44 mag. Made in 1983, jm stamp, micro groove.

Looks like it was cut with a back hoe!

What'd y'all think? Any ideas?

It shoots as bad as it looks too!

Cast lead bullets go all over the place, jacketed kinda group, more like a shotgun pattern though.

View attachment 1042670View attachment 1042668 View attachment 1042669View attachment 1042672View attachment 1042671

Bronze Supporter

- Messages

- 37,247

- Reactions

- 128,512

Wow! That's terrible! It hurts me to know a fellow firearms enthusiast is burdened with such a machine. I'd like to do my part to help. If you send me the rifle, I'll make sure it never bothers you again.

On a more serious note, that's unfortunate. I wonder if a smith could do something like sleeve the barrel or re-barrel it from one that turns up with a damaged receiver or use a blank barrel and fit it to the rifle. Once Ruger finishes spinning up Marlin production, I wonder if they'd be willing to help you out.

Best of luck!

Yeah, Ruger might help….. they wouldn't want their newly acquired Marlin line to compete with their Mini-14/30 rifles for shooting around corners and such…..

- Messages

- 269

- Reactions

- 432

This was typical for Marlin levers of that time period! A Marlin employee posted an excellent writeup on another forum years ago detailing the steps needed to product a functional barrel. Marlin skipped some of those steps to reduce cost.Marlin 94, 44 mag. Made in 1983, jm stamp, micro groove.

Looks like it was cut with a back hoe!

What'd y'all think? Any ideas?

It shoots as bad as it looks too!

Cast lead bullets go all over the place, jacketed kinda group, more like a shotgun pattern though.

View attachment 1042670View attachment 1042668 View attachment 1042669View attachment 1042672View attachment 1042671

What you see here is the results of only drilling the barrel, the next step of removing the ruff cuts did not happen. Most likely even the next step of stress relief was not done! After that one and only first drilling the barrel was button rifled.

If the owner of that Marlin had pushed a very tight patch through the barrel, the owner also would of noticed loose & tight spots in the bore as the tight patch moved through the barrel. Without stress relief of the barrel, metal tends to move back from where it was before the button rifling step.

With that said; If the barrel ain't right - nuth'in is right. In this case it is hard to make a silk purse from a sow's ear. Best outcome is to hand lap the bore very slowly. Attempt to even out the loose & tight spots. Pay very close to the bore diameter by using a micrometer and check the lead lap's diameter.

The loose & tights spots will be located where the sights are attached, roll markings, dove tail cuts, and surprisingly where the barrel is screwed into the receiver. Don't ask me how I know.

Foreverlost,

- Messages

- 14,902

- Reactions

- 27,422

Heck yea - give 'em a try as ask them - but don't get POd if they refuse. Typically a manufacturer's warranty ends with THAT particular Mfg. but ya never know - never hurts to ask.Yeah, Ruger might help

I have seen a barrel this bad but its not a fair comparison as it was a CVA .45 ML rifle barrel on my first kit built ML I had. Although it looked like yours (and maybe a touch worse) it shot very well.

That might have been a better option but Henrys have had their share of problems as well - including some pretty bad bores as well but at least you would be assured of it being taken care of.Frankly, if I'd have known what a dog this rig would be, I'd have bought a henry instead.

FWIW If you do ever decide on a Henry give it a very thorough inspection prior to buying - as should be done with any gun purchase.

I gave my Henry about 45 Minutes prior to buying only because of the issues I had read about.

Last Edited:

- Thread Starter

- #18

Maybe I should give them a call. If they keep the threads the same, should be an easy barrel swap.Yeah, Ruger might help….. they wouldn't want their newly acquired Marlin line to compete with their Mini-14/30 rifles for shooting around corners and such…..

Bronze Lifetime

- Messages

- 4,916

- Reactions

- 12,963

Some years ago I contacted Marlin about mine due to the ugly roll stamp dents into the bore. I don't remember exactly what they said, but it was a no-go, not a chance. I posted about it to on a different forum somewhere as I recall. There was even a guy who had a spare take-off barrel laying around that he sold me cheap, but the roll marks in it were just as bad so I never put it on.

For me it was a case of diminishing returns. I tinkered with it and got it shooting well enough for my purposes. I could have gone all out and put a lot of time, effort, and money into it at really made it right, but for my practical purposes it wouldn't have mattered. For precision shooting I have other rifles. For an open-sight lever gun with limited range like the 44 mag, 2-3moa was plenty good enough for me, especially since I'd typically shoot it without a scope and offhand. That, and the fact that it almost never leaves the safe. I have rifles back in there that haven't been shot in many years, and realistically I may never shoot again. As I get older I'm really starting to wonder why I still have them.

For me it was a case of diminishing returns. I tinkered with it and got it shooting well enough for my purposes. I could have gone all out and put a lot of time, effort, and money into it at really made it right, but for my practical purposes it wouldn't have mattered. For precision shooting I have other rifles. For an open-sight lever gun with limited range like the 44 mag, 2-3moa was plenty good enough for me, especially since I'd typically shoot it without a scope and offhand. That, and the fact that it almost never leaves the safe. I have rifles back in there that haven't been shot in many years, and realistically I may never shoot again. As I get older I'm really starting to wonder why I still have them.

- Thread Starter

- #20

Interesting. You hear all the time, "just buy a jm stamped marlin".This was typical for Marlin levers of that time period! A Marlin employee posted an excellent writeup on another forum years ago detailing the steps needed to product a functional barrel. Marlin skipped some of those steps to reduce cost.

What you see here is the results of only drilling the barrel, the next step of removing the ruff cuts did not happen. Most likely even the next step of stress relief was not done! After that one and only first drilling the barrel was button rifled.

If the owner of that Marlin had pushed a very tight patch through the barrel, the owner also would of noticed loose & tight spots in the bore as the tight patch moved through the barrel. Without stress relief of the barrel, metal tends to move back from where it was before the button rifling step.

With that said; If the barrel ain't right - nuth'in is right. In this case it is hard to make a silk purse from a sow's ear. Best outcome is to hand lap the bore very slowly. Attempt to even out the loose & tight spots. Pay very close to the bore diameter by using a micrometer and check the lead lap's diameter.

The loose & tights spots will be located where the sights are attached, roll markings, dove tail cuts, and surprisingly where the barrel is screwed into the receiver. Don't ask me how I know.

Foreverlost,

But what you say makes sense, the story by the old employee jives with what I'm seeing here.

I will try hand lapping it before I do anything else. I've never don't that before, but I understand the principle, and I believe I'm aware of the pitfalls associated with the procedure.

I don't want to mothball this rifle, but I also don't want to sell it to another unsuspecting shooter, unless it someone I just don't like!

Share This Discussion

Similar threads

- Replies

- 52

- Views

- 2K

- Replies

- 87

- Views

- 4K

Upcoming Events

New Classified Ads

-

-

-

-

Mag packs galore! CZ Scorpion, 300 blk, and CZ75/SP01/Shadow 2

- Started by HyenaHank

- Replies: 0

-

Frankford Arsenal Quick-N- EZ Case Tumbler Kit

- Started by misterarman

- Replies: 0

-

Aero Precision AR15 10.3 ATLAS R-One MLOK Handgaurd - Black

- Started by CoolBreeze808

- Replies: 0

-

Misc. Parts, scorpion barrel, 1911 grips, 10/22 parts

- Started by Wookie1

- Replies: 0

-

Aero Precision 10.5 Barrel/Gas Block Assembly

- Started by CoolBreeze808

- Replies: 0

-

-

Support Our Community

If our Supporting Vendors don't have what you're looking for, use these links before making a purchase and we will receive a small percentage of the sale