- Thread Starter

- #21

Had enough daylight left to get out to the range and pattern the 939. Put about 6 cylinders through it, best group at 25 yards was 6.5", worst was over 11, trying various different brands, as per the usual with a new .22lr. (this was just offhand, shooting DA, but I can usually get under 5" like that, without too much effort.) More concerning, almost every cylinder had at least one failure to fire, with primer strikes that weren't real convincing as to their sincerity.

I will try the newer spring, it does appear to be longer, but I suspect it's not a spring issue, but rather the excess movement of the cylinder. The cylinder, on close inspection, is able to move not just right and left, but up and down, and to rock forward enough to be causing light strikes. The hammer nose ( firing pin) does not appear to be worn, and protrudes fairly proud past the recoil shield. Once I try, and probably rule out the spring, I will focus on getting the cylinder to lock up a lot tighter.

The trigger isn't terrible in DA. There's a nice wall at the end of the pull, so I can get it most of the way there, get a clear sight picture, and then break the shot. After just a few cylinders, I was definitely noticing the sharp edges on the sides of the trigger, so those are going to need some shaping and smoothing.

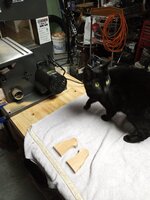

With the current grips, an HK speedloader just doesn't work. As I make new grips, I'll have to keep clearance for the speedloader in mind... having to load 9 individual rounds at a competition would be a deal breaker. Hopefully I can sort out something that's comfortable, but has enough clearance.

Just to be clear, I'm not frustrated or anything, this is about par for the course, and pretty much the sort of thing I was expecting. I will enjoy correcting all the little glitches, and probably end up with a decent little shooter for speed steel.

I will try the newer spring, it does appear to be longer, but I suspect it's not a spring issue, but rather the excess movement of the cylinder. The cylinder, on close inspection, is able to move not just right and left, but up and down, and to rock forward enough to be causing light strikes. The hammer nose ( firing pin) does not appear to be worn, and protrudes fairly proud past the recoil shield. Once I try, and probably rule out the spring, I will focus on getting the cylinder to lock up a lot tighter.

The trigger isn't terrible in DA. There's a nice wall at the end of the pull, so I can get it most of the way there, get a clear sight picture, and then break the shot. After just a few cylinders, I was definitely noticing the sharp edges on the sides of the trigger, so those are going to need some shaping and smoothing.

With the current grips, an HK speedloader just doesn't work. As I make new grips, I'll have to keep clearance for the speedloader in mind... having to load 9 individual rounds at a competition would be a deal breaker. Hopefully I can sort out something that's comfortable, but has enough clearance.

Just to be clear, I'm not frustrated or anything, this is about par for the course, and pretty much the sort of thing I was expecting. I will enjoy correcting all the little glitches, and probably end up with a decent little shooter for speed steel.

)

)