I have been wanting to make some of these things for a while. I had a few guys come into the shop and we got to talking, I find out one of them is a "blade smith". After some discussion on material he suggested O1 tool steel.

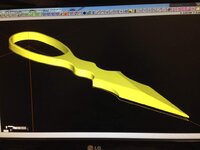

I got busy drawing them up

Then over to the machine

The first few I cut were aluminum, easier to proof the program and set up in something cheap and easy to machine.

Found out the ball groove was a little deep, so I backed it off and cut some steel.

And since I went to the trouble to make one, I figured I should at least make 12.

I also got a piece of steel from the blade smith that I was able to get 2 out of.

I got busy drawing them up

Then over to the machine

The first few I cut were aluminum, easier to proof the program and set up in something cheap and easy to machine.

Found out the ball groove was a little deep, so I backed it off and cut some steel.

And since I went to the trouble to make one, I figured I should at least make 12.

I also got a piece of steel from the blade smith that I was able to get 2 out of.