I'm working on a Tabuk build, just got my barrel - now I understand what "virgin barrel" means - the extractor cut is there, but that's it. Seems like it has an extra "step" to the barrel too that might need some lathe work. None of channels for the barrel pins are cut nor is the gas port cut... so I'm going to need to mill those in as I set the barrel - fortunately I'll be able to really headspace it properly!

Edit - here's pictures of what I have:

Looks like the chamber is set to go for the extractor:

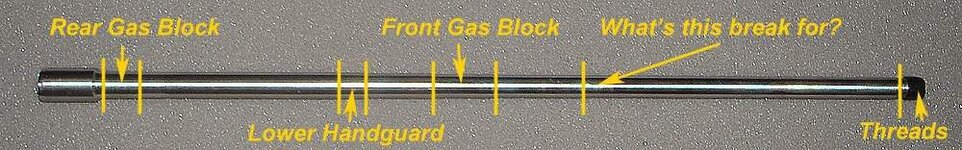

The barrel was machined in a stepwise fashion. I've gone through and annotated the steps I think I understand, but there's one that is forward of the front gas block and rear of the threads that makes no sense... there's also no exact provision for the front sight block:

Edit - here's pictures of what I have:

Looks like the chamber is set to go for the extractor:

The barrel was machined in a stepwise fashion. I've gone through and annotated the steps I think I understand, but there's one that is forward of the front gas block and rear of the threads that makes no sense... there's also no exact provision for the front sight block: