- Messages

- 5,749

- Reactions

- 18,149

- Thread Starter

- #121

Just curious, how are you shaping those? Do you have a jig of some kind? What tools are you using? I really like the different grips you've been making and I may want to try and tackle that myself. I've got some zebrawood, purpleheart and some nice maple I'd like to try.

Nothing fancy. I have some crap GI grips that I have been using to trace on wood using a sharpie

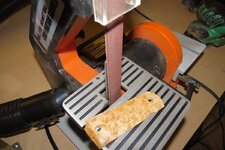

Then cut out with the band saw. I clamp on the GI grips back on and use the holes to guide the drill press

Then I sand the rounded grip side using a 1x30 belt sander. Just doing it by eye. 80 grit to get the bulk of it sanded round and then finish with 400 grit

I finish the grip screw holes by using a step drill bit I had that works really well, I drill down through the 1/4" step and create the little ledge for the screw with the 9/32" step

I create the space on the back with a 3/8th bit with a starter point like this one

I then finish with a dremel sanding drum to get the space for the thumb safety and mag ejector finished

then Im experimenting with finishing techniques like the sand filling technique in this video (just remember boiled linseed oil oxidizes so may set rags soaked with it on fire if left in a pile)

Im also trying tru-oil. Though I got a recipe for linseed oil + turpentine + minwax polyurethane from the guy at Gilmer to try as well