- Messages

- 6,824

- Reactions

- 17,613

...

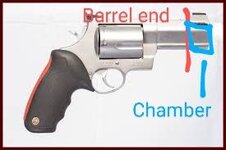

I never claimed to know more than a reloading manual. I assumed "lead is lead" and went by the weight. WRONG, I didn't know and I have learned. Anyhow, lead will now only be shot with Trailboss, like I do in my 357.

...

I for one appreciate the story. No judgment on my part. I would say that this does deserve a spot in the reloading mistakes thread.