- Messages

- 261

- Reactions

- 523

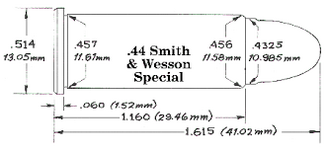

A while back I bought a box of "Ultramax" cowboy ammo in.44Spl.

Pulled some bullets,, they were .427, they didn't work so good in the .44Mag, it wanted some .429>.430s.

Pulled some bullets,, they were .427, they didn't work so good in the .44Mag, it wanted some .429>.430s.